How to enhance the direct handling of the gearshift shift inhalation

A direct-operated transmission is a type of transmission that the driver can directly manipulate the transmission's joystick toggle the internal gearshift to achieve a vehicle shift. It is widely used in most cars and long-haul trucks (such as pickup ). Directly operated transmission with high transmission efficiency, cost advantages and other characteristics, but the direct-type transmission vehicle vibration control is difficult, shift feeling is also an important reason for restricting its development. Here to introduce a way to enhance the shift of the conventional transmission shift in the hope that the development of direct-type transmission can make a little try and advance.

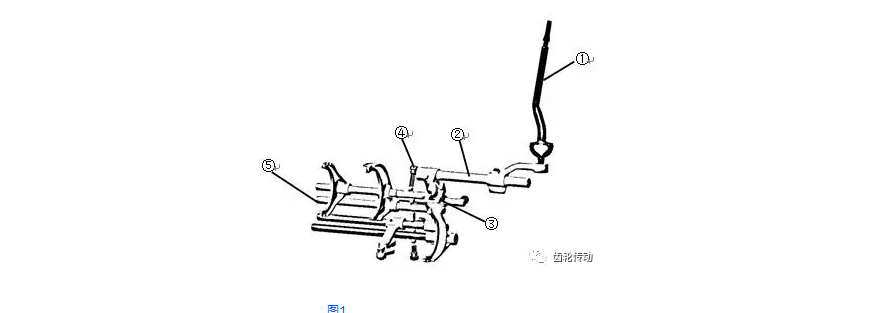

Directly operated transmissions are designed so that the operating lever of the transmission and all shift control devices must be located on the transmission cover, and the transmission should be placed near the driver's seat before it can be realized. It is this unique structure, the transmission gearshift mechanism in the layout of the existence of crowded space, the cumulative gap between the parts, the overall shift shift feel poor, to improve the space is small, for the above problems, we continue to try , And finally by adding a shift block and locating pin on the mechanism to solve the problem of shift in the suction difference, and at the same time reduce the shift of the empty stroke ratio, shift feeling significantly improved. First of all, through the following Figure 1 to understand a direct control of the transmission shift mechanism.

Note: ① joystick ② shift gear shaft parts ③ the file dial block ④ self-locking spring ⑤ fork and fork fork fork

Figure 1 is a love letter produced by the direct control of the transmission gear shift control mechanism, the body through the ① joystick - ② shift gear shaft - ③ shift block - ⑤ fork fork and fork Transfer order to achieve the shift, the figure can be seen, the joystick ball head and the first choice of gears connected to the gear, and then by selecting the gearshaft and the gear shift block to connect the block, the dial and then pass to the dial Fork and synchronizer gear sets, through our actual mapping of the body, the process of accumulation of about 1.5mm gap, if the lever ratio in accordance with the 6 to calculate the ball to the cab, empty trip reached 9mm, accounting for the total trip 10 %, Which is a bad feeling for the shift feel. In this body, the force acting on the driver's hand mainly comes from the mechanism of the self-locking spring force, the synchronizer spring force and the frictional resistance of the transmission mechanism.

In order to effectively improve the above problems, we have added a shift block on the shift shaft, adding a locating pin to the original control seat (the application of the locating pin has been more successful in many models of passenger cars and commercial vehicles Experience), see Figure 2 below

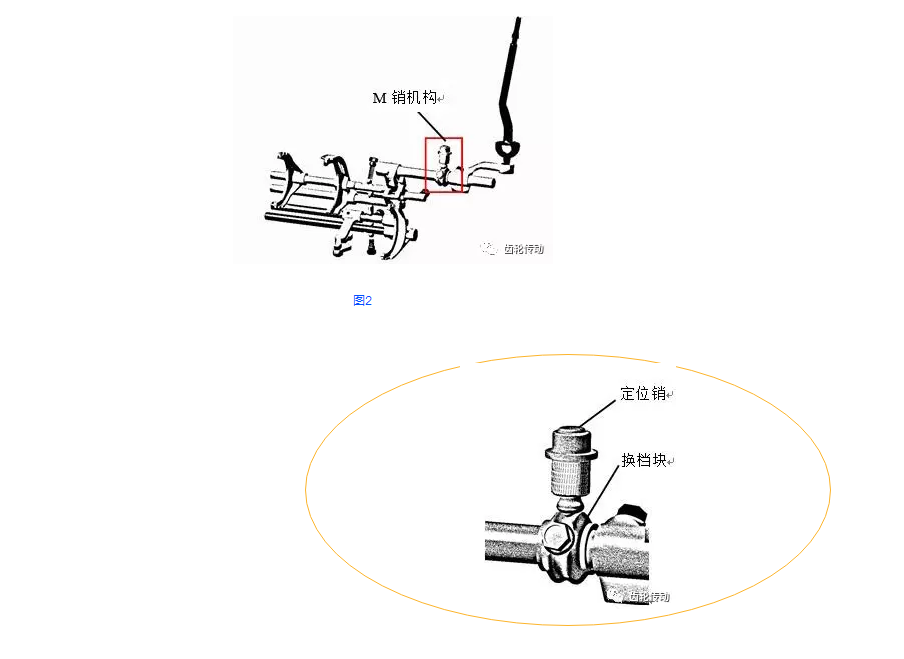

Figure 3 is a partial enlarged view of the M pin mechanism in Figure 2, by adding the shift block in Figure 3, the original design can bring the following optimization:

1, the front has been mentioned in the original operation of the transfer order and the gap between the various components exist, increase the shift block, we can design the original body in the shift head and gear shift gap, fork and The gap of the gear is contained in the stroke design of the shift block so that the driver can only feel the gap between the joystick and the selector gear during operation, and this gap can be designed to be small.

2, in order to ensure the overall size of the transmission shift force, we must put the original body of the force adjustment small. In the process of optimizing the original gearshift performance of the program, we have done a practical verification, that is, do not make other adjustments to the organization, but only to increase the stiffness of the self-locking spring, through the actual measurement, we found that in addition to the spring force on the body The impact of the system also increases the frictional resistance. On the contrary, we reduce the self-locking spring force, the system's frictional resistance will become smaller, which is the structure of the force in the body is excellent.

3, the increase in the shift block on the gearshift mechanism of the neutral position has a precise positioning, file selection when the file stalls than the improvement before the improvement of a lot, or can be said to have been completely avoided due to operation or processing Ultra-poor to bring a slight shift jam phenomenon, which is what we like to see.

Then in the shift block and positioning pin design process should pay attention to what elements, summed up roughly the following two points:

1, the main design of the gear block design is actually a common M-slot design concept, the design should be a few factors in the shift process to consider a comprehensive, through the front of Figure 2 can clearly see each work The role of the force in that node, the role here is nothing more than the power and resistance of two, like the shift block in the climbing stage is the resistance, downhill stage is the power, and the system of friction or drag force has been resistance The role of each gear if the fork on the shaft is also designed to have M slot, it should also consider the role of the various forces to design a reasonable node, can not be counterproductive. Here the introduction of a concept, called positioning pin climbing and downhill travel ratio, hereinafter referred to as travel ratio. For example, in the M slot design of the shift block, the stroke ratio of the M-groove on the fork shaft should be taken into account. The design principle is preferably the stroke ratio on the fork shaft is slightly smaller than the stroke ratio of the shift block. The role of the shift in the process of force should also be considered, only a few of the relevant design of the appropriate force before they can pick the gear when the suction force has a substantial help.

2, positioning pin design, should pay special attention to the interference in the shift block situation, should be in the design process to do a good job of simulation and verification of the drawings.

Obviously, by adding the shift block and locating pin on the original body, the performance of the direct-operated transmission is improved greatly. However, there are many factors influencing the shift force in the transmission assembly. During the course of the study, we also found that there are many other details that require more in-depth research and innovation, and we will continue to explore in this area to share with you the benefits of technological innovation.

Contact us

Zhoushan Yuandong Gear Co.,Ltd.Address:Liuheng Town, Putuo District, Zhoushan City, Zhejiang, China